Reliable Solutions: Undercarriage Components for Heavy Equipment

Quality undercarriage parts play a significant duty in guaranteeing the smooth procedure and longevity of heavy machinery. In this conversation, we will check out the value of investing in superior undercarriage components, common wear challenges faced by heavy equipment operators, the advantages of timely replacements, guidelines for choosing reliable suppliers, and essential maintenance suggestions to extend the life expectancy of undercarriage components.

Value of Quality Undercarriage Components

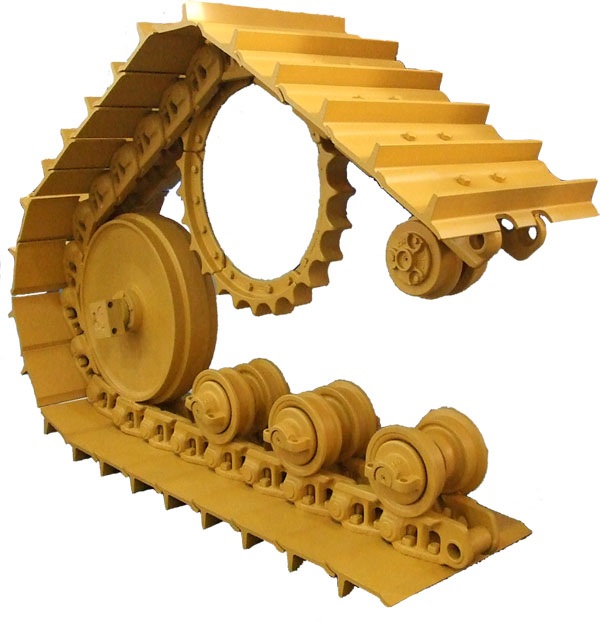

Quality undercarriage components are important components in making sure the resilience and efficiency of heavy equipment. The undercarriage of tools such as excavators, excavators, and track loaders plays a vital duty in sustaining the maker's weight, providing stability on different terrains, and taking in the impact of irregular surfaces. By purchasing premium undercarriage components, drivers can substantially expand the life-span of their equipment and lower the danger of unexpected break downs.

One key advantage of using high quality undercarriage components is the improvement of overall equipment performance. Durable tracks, idlers, rollers, and sprockets decrease rubbing and make certain smoother activity, eventually leading to raised efficiency and performance on task websites. Trustworthy undercarriage parts decrease downtime for maintenance and fixings, permitting operators to optimize their functional hours and project deadlines.

Usual Undercarriage Put On Problems

Advantages of Timely Replacement

One trick benefit of prompt undercarriage component substitute is boosted equipment uptime. By changing used parts before they fail, the risk of unforeseen failures is minimized, reducing downtime for fixings and maintenance. This proactive strategy not just keeps the hefty machinery operational yet likewise protects against possible damage to other parts that could arise from a stopping working undercarriage.

Furthermore, changing undercarriage parts without delay can enhance overall efficiency. A well-maintained undercarriage guarantees ideal machine performance, allowing for smoother procedure and greater efficiency in completing tasks. This, in turn, results in enhanced job website performance and cost savings by staying clear of hold-ups and interruptions caused by underperforming machinery. Investing in timely undercarriage component substitute is an aggressive strategy that pays off in terms of boosted effectiveness and lowered functional webpage expenses.

Picking the Right Undercarriage Distributor

Choosing the suitable undercarriage provider is an important decision that substantially influences the performance and maintenance of heavy machinery. When choosing a vendor for undercarriage components, several variables need to be taken into consideration to make certain ideal efficiency and cost-effectiveness. A distributor that offers a wide selection of undercarriage parts for various heavy equipment brand names and versions can be beneficial as it offers extra choices to satisfy specific requirements.

Stabilizing integrity, top quality, and cost-effectiveness is essential when choosing the best undercarriage distributor for hefty equipment. By carefully evaluating these variables, you can choose a provider that meets your requirements and adds to the effective performance and maintenance of your heavy machinery.

Maintenance Tips for Extended Life-span

To guarantee an extensive life expectancy for hefty machinery undercarriage components, carrying out a proactive maintenance routine is essential. Frequently checking undercarriage components such as track chains, idlers, rollers, and gears for wear and tear is vital. Any type of indications of damages or too much wear need to be without delay addressed to avoid additional deterioration and prospective failures. Furthermore, keeping the undercarriage clean from dirt, debris, and harsh products can substantially extend its life-span. Greasing moving parts according to maker referrals helps in reducing friction and protect against premature wear. Checking track tension and positioning is likewise essential to avoid irregular endure the undercarriage components. Buying quality undercarriage components from respectable suppliers is just as crucial for guaranteeing long life. By following these upkeep pointers carefully, hefty equipment proprietors can optimize the performance and longevity of their undercarriage components, ultimately decreasing downtime and operational costs.

Verdict

In verdict, top find more info quality undercarriage parts are necessary for the reliable operation of hefty machinery. Picking a trustworthy distributor and complying with appropriate maintenance practices are essential to making sure the expanded life-span of undercarriage elements.

Too much wear and tear on undercarriage components of heavy equipment can lead to substantial functional obstacles and increased upkeep prices. Normal inspections, correct upkeep, and prompt substitutes of worn undercarriage components are vital to minimize these usual wear troubles and guarantee the optimal performance of hefty equipment.

A distributor that supplies a broad option of undercarriage components for numerous hefty machinery brands and models can be helpful as it gives more choices to fulfill details demands.

By complying with these upkeep tips diligently, heavy her latest blog machinery proprietors can optimize the efficiency and durability of their undercarriage components, inevitably reducing downtime and operational prices.